The Drop Tower enables visitors to repeatably drop a racquetball 20 feet onto an angled surface. The angle and material of the surface can be changed, enabling users to experiment with the 2 variables and discover how they affect the trajectory and bounce height of the ball. The targets provide a goal for visitors to aim for, though many simply experiment on their own.

Process

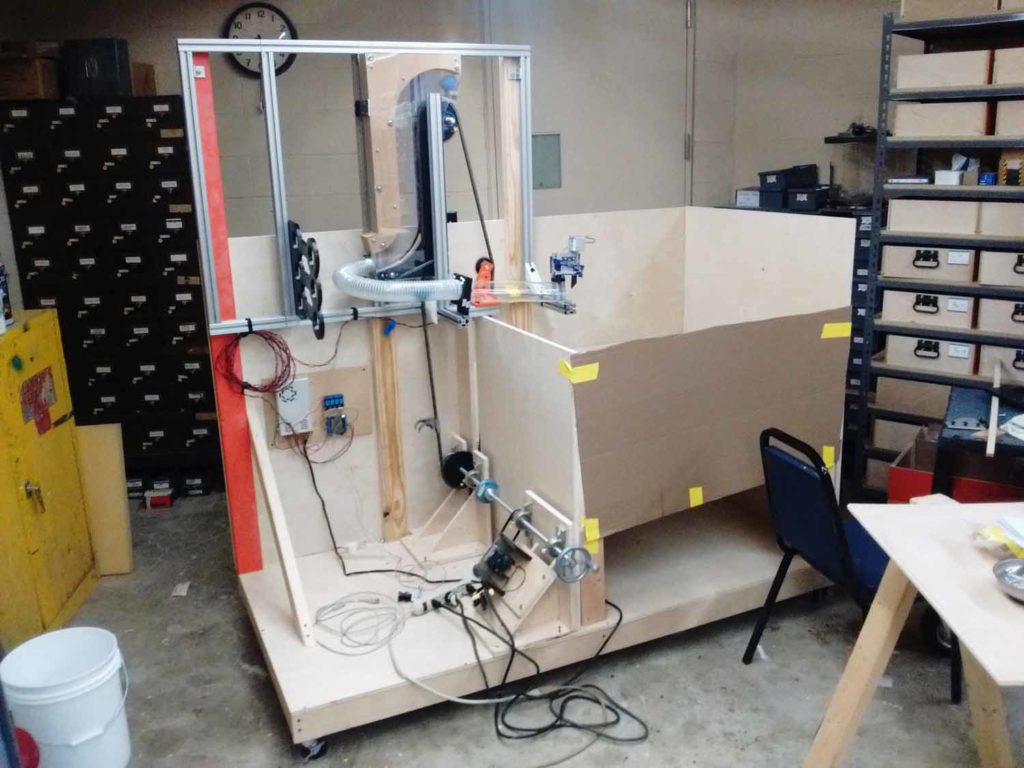

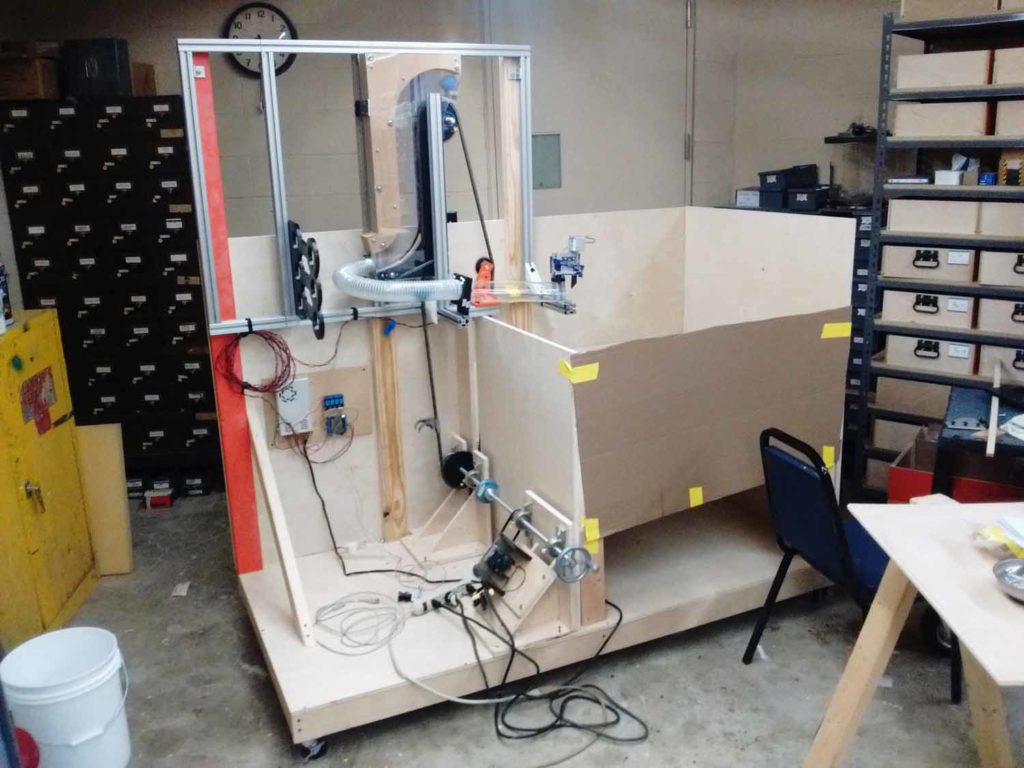

We built and tested several prototypes to determine whether or not our plans were visitor-friendly, the reliability of the ‘dropper’ mechanism, and the feasibility of the chain conveyor. See images below for more details…

Challenges

- Reliability was a serious concern since some of the working parts are 20 feet in the air, and difficult to access.

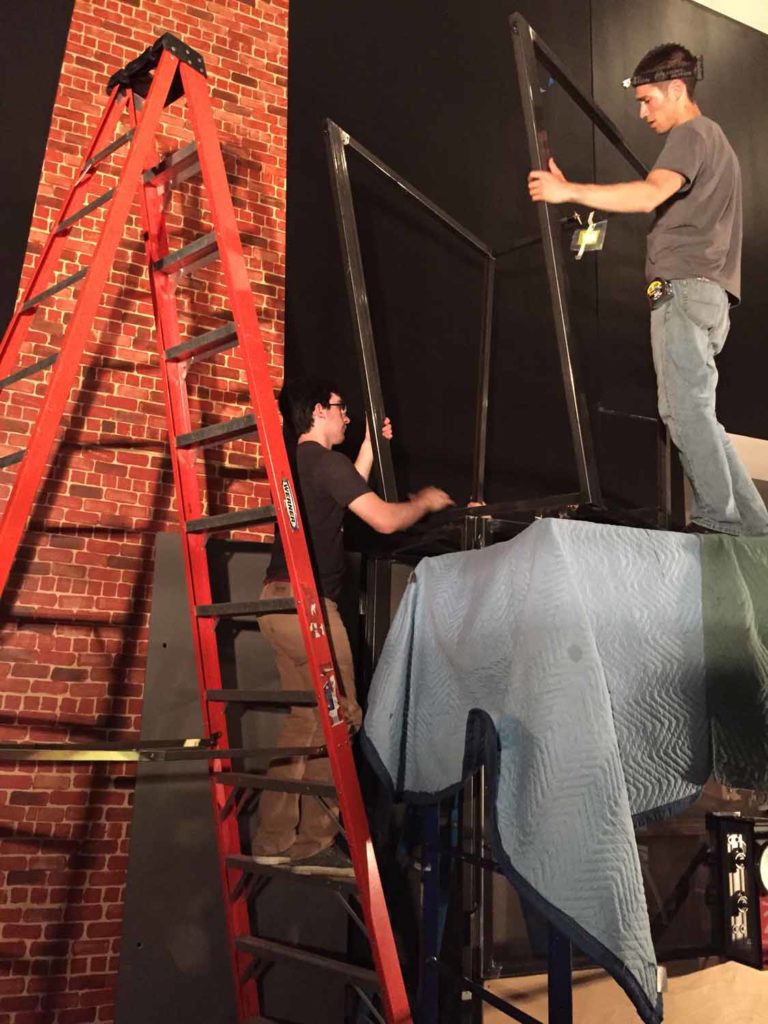

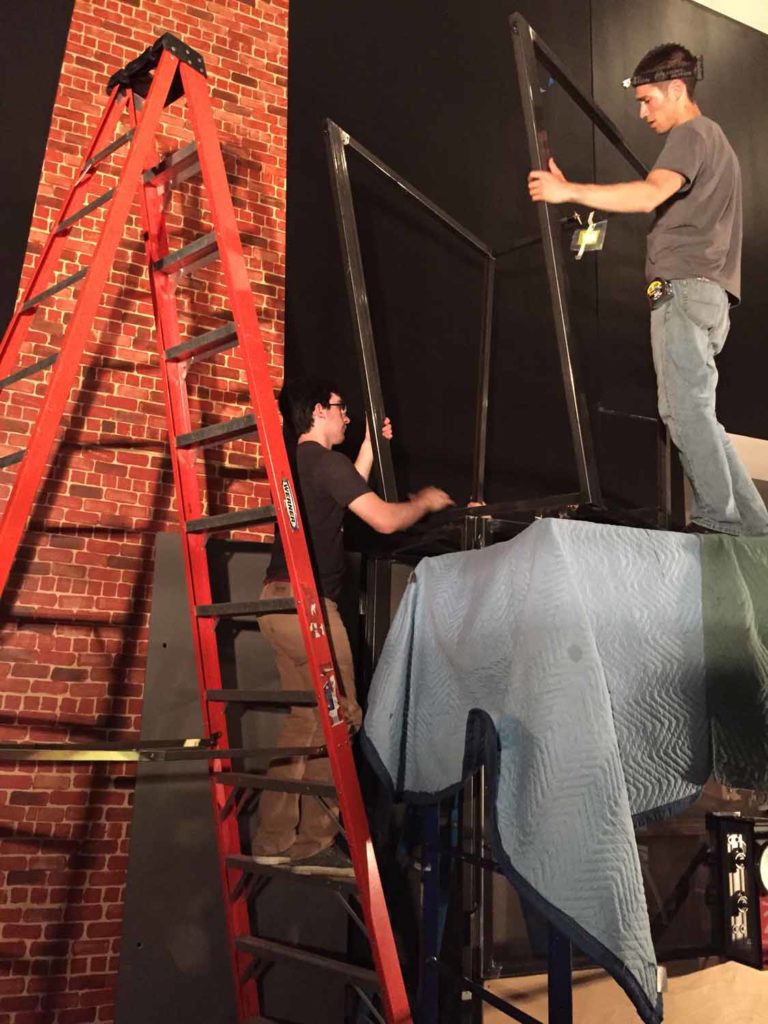

- The height of the design was difficult since the museum lacks an appropriate lift or convenient ceiling lift points. The shop ceiling is not much over 8 feet, and the freight elevator is very small, so the components were built in sub-assemblies, test-fit and finished in the shop, and fully assembled on the exhibit floor

Design Details

- Gear reduction and a rotary damper prevents visitors from spinning the Prism in an uncontrolled fashion

- Controls for steps 1,2, and 3 (Load, Adjust, Drop) are arranged in sequential order for intuitive operation

- An angle indicator makes the experiment replicable

Detail of bounce-height scale

Detail of prism rotation indicator

Detail of top module and electrical boxes

Detail of user controls

Our first prototype was designed to test some of the mechanical elements, and see how visitors would interact with the component. We found that having 3 different ball types was too much for most visitors, so we eliminated the wiffel ball and golf ball, and kept the racquetball.

Testing to determine the trajectory of dropped balls

2nd prototype to determine reliability of top module mechanism. The testing revealed some reliability issues that we were able to solve before the Drop Tower was installed.

Testing the 2nd prototype at full height to determine how the chain would act. Thankfully, we found no problems!

I completed the final Overall design in Rhino at the same time Cole was completing the Top Module design in Solidworks. I then combined our designs and completed final construction drawings in Solidworks.

Fabrication in the shop

We had to set up during off-hours, since the museum was open 7 days a week

Karl helping with final electrical hookups before final assembly

Construction Drawings

Below are examples of construction drawings I created with Solidworks. They were given to a commercial welding company, who fabricated and delivered the pieces.